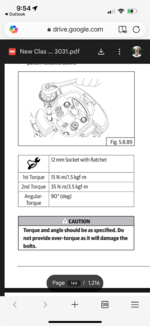

Any more updates? Is the 410 still performing well, oil consumption issues, etc? How about the fuel type you are using (octane) and fuel mileage. Seriously considering this kit for my Meteor that is already fitted with a Hunter throttle body. Thank youI use a digital torque wrench, evenly criss cross the bolts up to 25 nm then in 2.5nm rises goes around till 35nm, have a Coffee and then up to 37!

Worked for me!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

J-Engine 410cc Thread

- Thread starter sam2019

- Start date

Let me throw some comments in here about the 410 kit. I have a ‘22 Meteor and a ‘23 Classic reborn. Where I in live in hill country, they needed some help. Both got a DNA filter & cover, fuelx lite, a decat, plus the 16t countershaft sprocket. Meteor was good to go. The Classic still seemed a bit off. Maybe riding position, lack of a fly screen, or whatever, dunno.

So the Classic got a Kent cam and a Red Rooster exhaust. Kept the baffle in for sound, but modified it for a bit more flow. Performance didn’t seemed to be much enhanced, so went for the big bore kit. This changed everything.

Easy to install, took less than a few hours. Started right up, settled in to a nice idle, and after about 20 minutes of that, took it for a ride. I get a little popping on downshifts and sometimes accelerating it seems to hit a flat spot for half a second, in the lower rpm’s. Aside from that, it put the bike right where I want it.

I use to shift about the 5 to 5.5k rpm range, kept the engine higher in the rpms, but now it pulls very strong from 3.5k rpms and I can shift in the 4 to 4.5 rpm range. The roads I drive do not require speed, but power. And now I have it.

I use the Classic for (and is setup for) back roads cruising. I use the Meteor for (and is setup for) longer straight line trips. But now I’m going to up the Meteor to 410. I ordered the gasket set and a new Himalayan piston. I’ll take the cylinder from the Classic and have it bored (just need to locate a machine shop). I probably won’t upgrade to a hotter cam or exhaust.

FYI.

So the Classic got a Kent cam and a Red Rooster exhaust. Kept the baffle in for sound, but modified it for a bit more flow. Performance didn’t seemed to be much enhanced, so went for the big bore kit. This changed everything.

Easy to install, took less than a few hours. Started right up, settled in to a nice idle, and after about 20 minutes of that, took it for a ride. I get a little popping on downshifts and sometimes accelerating it seems to hit a flat spot for half a second, in the lower rpm’s. Aside from that, it put the bike right where I want it.

I use to shift about the 5 to 5.5k rpm range, kept the engine higher in the rpms, but now it pulls very strong from 3.5k rpms and I can shift in the 4 to 4.5 rpm range. The roads I drive do not require speed, but power. And now I have it.

I use the Classic for (and is setup for) back roads cruising. I use the Meteor for (and is setup for) longer straight line trips. But now I’m going to up the Meteor to 410. I ordered the gasket set and a new Himalayan piston. I’ll take the cylinder from the Classic and have it bored (just need to locate a machine shop). I probably won’t upgrade to a hotter cam or exhaust.

FYI.

The liner is not fit to be bored out. It has 2 layers and the out layer is a different material, not fit as cylinder wall. A new liner will be needed. Touting my own horn here but I bet you ordering another set from us will be cheaper.’ll take the cylinder from the Classic and have it bored

you have PM - such things of monetary nature are best discussed in privateCan I just purchase a new cylinder from you or can I send this one to you and have a new sleeve installed or do some sort of exchange?

Hello All,

I have the 410BB in transit to me as I'm writing this. And I've been following a fellow RE J350 rider who has done the conversion to his Classic. The question of final compression ratio has come up. We know that the description on the HT website ad says a 3-5% C/R increase is expected. We are wondering what this is based on? Without access to both Himalayan 411 & J350 heads and pistons to measure combustion chamber volumes from, and given the differences in the piston depressions, we are hoping someone has taken both pre and post conversion cranking pressure readings, and can provide these to the group. A 5% increase in compression ratio would yield a new CR of 9.975:1, however the new bore sweep volume coupled with the J350 head volume would indicate a CR closer to 11:1. Can anyone provide something more definitive?

I have the 410BB in transit to me as I'm writing this. And I've been following a fellow RE J350 rider who has done the conversion to his Classic. The question of final compression ratio has come up. We know that the description on the HT website ad says a 3-5% C/R increase is expected. We are wondering what this is based on? Without access to both Himalayan 411 & J350 heads and pistons to measure combustion chamber volumes from, and given the differences in the piston depressions, we are hoping someone has taken both pre and post conversion cranking pressure readings, and can provide these to the group. A 5% increase in compression ratio would yield a new CR of 9.975:1, however the new bore sweep volume coupled with the J350 head volume would indicate a CR closer to 11:1. Can anyone provide something more definitive?

well, a percentage can be elicited simply by using the same psi measuring tool on a stock engine and the 410. Thats what we did. In real life this increase is not big enough to create any trouble. Somewhere here are short clips of the measurements we did on stock j350 and BB. If in some circumstances, e.g. a trip in a country with very bad fuel (Africa, India) there is a head mod that is simple to do with a dremel that will reduce by up to 10%, depending on the amount of material taken off the head.

I have an update on my 410BB kit on my ‘23 Classic.

Initially everything appeared to be working fine. But as I put more miles on the bike (I have about 300 on it since the install), I noticed a couple of things. One, I was getting a strange noise on start up, but it would go away after running for a few minutes. Second, I felt as though I was losing power. The engine noise definitely sounded like fuel ignition issue.

So, I decided to check valves, cam timing etc, As I was starting the bike and was leaning forward to listen for the sound, I saw a vapor blowing out of the engine just above the spark plug. Putting my hand down there, I could feel the air coming out in a regular pulse from between the cylinder and head.

Tearing the engine down, I went straight for the head bolts to check the torque. My torque wrench was still on the same setting as when I installed the kit. All the bolts were loose about the same. So I just retorted them (18n/m) and put everything back together.

Started up fine, no odd sounds or noticeable cylinder head leaks. Took it out for a run, ran great.

Any ideas as to what may have caused this?

Initially everything appeared to be working fine. But as I put more miles on the bike (I have about 300 on it since the install), I noticed a couple of things. One, I was getting a strange noise on start up, but it would go away after running for a few minutes. Second, I felt as though I was losing power. The engine noise definitely sounded like fuel ignition issue.

So, I decided to check valves, cam timing etc, As I was starting the bike and was leaning forward to listen for the sound, I saw a vapor blowing out of the engine just above the spark plug. Putting my hand down there, I could feel the air coming out in a regular pulse from between the cylinder and head.

Tearing the engine down, I went straight for the head bolts to check the torque. My torque wrench was still on the same setting as when I installed the kit. All the bolts were loose about the same. So I just retorted them (18n/m) and put everything back together.

Started up fine, no odd sounds or noticeable cylinder head leaks. Took it out for a run, ran great.

Any ideas as to what may have caused this?

As per manual it is suggested to re-torque those bolts after 500km, which is approx your 300 miles. It is also suggested to use new bolts every time one changes anything (like the cylinder) but I have to say hardly anyone does that and we have re used the same bolts multiple times without negative effects.Any ideas as to what may have caused this?

I did watch the one YouTube video on a big bore install on a 350 where the mechanic didn’t torque the head bolts (or any other for that matter). I guess he just had a feel for it!As per manual it is suggested to re-torque those bolts after 500km, which is approx your 300 miles. It is also suggested to use new bolts every time one changes anything (like the cylinder) but I have to say hardly anyone does that and we have re used the same bolts multiple times without negative effects.

I have had to reuse the head bolts 3 times so far, I have a digital torque wrench and do it in stages of 5 or so and wander off for a break before returning and going up.

18 nm seems low, I thought it was about 40?

18 nm seems low, I thought it was about 40?

I got these specs from the Royal Enfield Owners Group. There was a master list posted in the Meteor, Classic, Hunter, and Bullet section. They do seem low. But since you mentioned it, I look further.I have had to reuse the head bolts 3 times so far, I have a digital torque wrench and do it in stages of 5 or so and wander off for a break before returning and going up.

18 nm seems low, I thought it was about 40?

yes, he has, having done that a gazillion times. but I also write somewhere not to do that and use a torque wrench instead.I guess he just had a feel for it!

they dont believe their own specs. for one none of the mechanics I know uses new head bolts EVER. plus if your try to order them (which I did multiple times) you dont get them!!starting to wonder about RE specs.